Commercial Banana Chips Processing Line Capacity: 300-1000 Kg/Hr

30000.00 - 100000.00 USD

Minimum Order Quantity :

1

Set/Sets

Control System

PLC Control

Voltage

380 Watt (w)

Henan Gelgoog Machinery Co., Ltd.

Ms Emily Ge

Zhengzhou, Henan

...More

7th Floor, Building - 8, Jingkai Square, No.1507, Hanghai East Road, Free Trade Zone, Zhengzhou, Henan, 450000, China

View Number

Product Details

Control SystemPLC Control

Voltage380 Watt (w)

FeatureLow Noice, ECO Friendly, Lower Energy Consumption, High Efficiency, Compact Structure

Capacity300-1000 Kg/hr

Product ShapeOther

Installation TypeFree Stand

Power1.1 Watt (w)

Weight (kg)360 Kilograms (kg)

MaterialStainless Steel

WarrantyCE,ISO9001

Product TypeNew

ColorOther

ComputerizedYes

Dimension (L*W*H)1000*500*700 Millimeter (mm)

General UseProcessing banana chips

AutomaticYes

Sample AvailableYes

CertificationsCE,ISO9001

Main Export Market(s)Australia, South America, Eastern Europe, Africa, North America, Middle East, Asia, Western Europe, Central America

FOB PortTianjin,Qingdao,Shanghai

Main Domestic MarketAll India

Packaging DetailsWooden Packing as Export Standard

Sample PolicyContact us for information regarding our sample policy

Delivery Time15 Days

Supply Ability200 Per Year

Payment TermsOthers, Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union

Offered ByHenan Gelgoog Machinery Co., Ltd.

BrandGelgoog

Product Description

Our well certified firm engaged in offering a wide array of Commercial Banana Chips Processing Line to our valued customers.

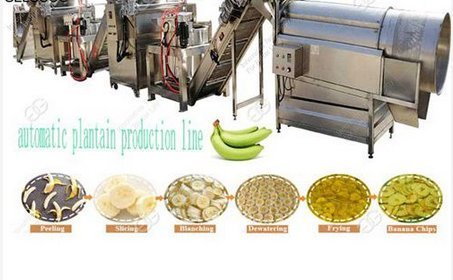

Introduction of commercial plantain/banana chips production line:

This hot selling plantain chips making line is designed for small and medium chip makers. We offer three different models of 150 kg/h, 300 kg/h, 500 kg/h ,1000kg/h and more other capacity for you. This commercial plantain chips production line is cheap and efficient, and is the best choice for processing banana/plantain chips.

Main equipment of commercial plantain chips making machine:

Peeling-slicing-frying-deoiling-seasoning-packing

Features of hot selling plantain chips making line:

1,This banana/plantain chips making line is automated, which can save labor and reduce the cost of machine operation.

2, All machines are made of stainless steel 304.

3, Advanced technology guarantees the plant lower energy cost and lower labor cost.

4, The installation project can be customized according to customers' factory.

Introduction of the main machine for plantain chips making machine :

1.Plantain chips peeling machine:This machine can peel the banana with high efficiently. On the premise of not damaging the pulp of the banana, it can completely separate the peel of the banana, and the machine can automatically separate the peel.

2.Plantain Chips Cutting Machine: this machine is new designed and developed, it is special used to slice plantain to be slice. The thickness of finished plantain chips is adjustable. Made of stainless steel 304.

3. Plantain chips frying machine:oil-water separation system is used. This extends the life of the oil. This kind of fryer is a continuous work, automatic feeding and automatic unloading, the conveyor unloads the material through the conveyor.

4. The degreasing machine adopts anti-impact system and adopts centrifugal principle, electromagnetic brake, digital automatic control, stainless steel and other equipment. Food will not be thrown out during deoiling process.

5, Plantain chips seasoning machine:The seasoning machine can realize automatic mixing materials, so also called it the drum food seasoning machine, easy to use.

Advantages of the production of plantain chips:

1, Stainless steel, easy to operate, high productivity and high efficiency.

2, Made of stainless steel, advanced technology, long service life.

3, The machines meet stringent international quality standards.

4, Very reasonable price for the equipment.

Pre-sale services :

Act as a good advisor and assistant of clients; enable them to get rich and competitive

from the returns of their investment.

1) Select suitable equipment model.

2) Design and manufacture products according to clients special requirements.

3) Train technical personnel for clients.

4) Professional suggestion for customer.

Services during the sale :

Respect clients; devote ourselves to improving the total value of clients.

1)take photos(including raw material, semi-products, final products, and loading products)

2) Pre-check and accept products ahead of delivery.

3) Prepare all clearance documents, so that the customer clearance smoothly.

After-sale services :

Provide considerate services to minimize clients worries.

1) Provide civil engineering drawings of the equipment.

2) Free training(including installation,maintenace) to every customer.

3) Install and debug the equipment, ensure the dryer running smoothly.

4) Examine the equipment regularly.

5) Take initiative to eliminate the troubles rapidly at site.

6) Distribute the guarantee fittings door-to-door.

7) Provide technical exchange and support.

Introduction of commercial plantain/banana chips production line:

This hot selling plantain chips making line is designed for small and medium chip makers. We offer three different models of 150 kg/h, 300 kg/h, 500 kg/h ,1000kg/h and more other capacity for you. This commercial plantain chips production line is cheap and efficient, and is the best choice for processing banana/plantain chips.

Main equipment of commercial plantain chips making machine:

Peeling-slicing-frying-deoiling-seasoning-packing

Features of hot selling plantain chips making line:

1,This banana/plantain chips making line is automated, which can save labor and reduce the cost of machine operation.

2, All machines are made of stainless steel 304.

3, Advanced technology guarantees the plant lower energy cost and lower labor cost.

4, The installation project can be customized according to customers' factory.

Introduction of the main machine for plantain chips making machine :

1.Plantain chips peeling machine:This machine can peel the banana with high efficiently. On the premise of not damaging the pulp of the banana, it can completely separate the peel of the banana, and the machine can automatically separate the peel.

2.Plantain Chips Cutting Machine: this machine is new designed and developed, it is special used to slice plantain to be slice. The thickness of finished plantain chips is adjustable. Made of stainless steel 304.

3. Plantain chips frying machine:oil-water separation system is used. This extends the life of the oil. This kind of fryer is a continuous work, automatic feeding and automatic unloading, the conveyor unloads the material through the conveyor.

4. The degreasing machine adopts anti-impact system and adopts centrifugal principle, electromagnetic brake, digital automatic control, stainless steel and other equipment. Food will not be thrown out during deoiling process.

5, Plantain chips seasoning machine:The seasoning machine can realize automatic mixing materials, so also called it the drum food seasoning machine, easy to use.

Advantages of the production of plantain chips:

1, Stainless steel, easy to operate, high productivity and high efficiency.

2, Made of stainless steel, advanced technology, long service life.

3, The machines meet stringent international quality standards.

4, Very reasonable price for the equipment.

Pre-sale services :

Act as a good advisor and assistant of clients; enable them to get rich and competitive

from the returns of their investment.

1) Select suitable equipment model.

2) Design and manufacture products according to clients special requirements.

3) Train technical personnel for clients.

4) Professional suggestion for customer.

Services during the sale :

Respect clients; devote ourselves to improving the total value of clients.

1)take photos(including raw material, semi-products, final products, and loading products)

2) Pre-check and accept products ahead of delivery.

3) Prepare all clearance documents, so that the customer clearance smoothly.

After-sale services :

Provide considerate services to minimize clients worries.

1) Provide civil engineering drawings of the equipment.

2) Free training(including installation,maintenace) to every customer.

3) Install and debug the equipment, ensure the dryer running smoothly.

4) Examine the equipment regularly.

5) Take initiative to eliminate the troubles rapidly at site.

6) Distribute the guarantee fittings door-to-door.

7) Provide technical exchange and support.

Company Details

As a professional food processing machinery manufacturer, there are many kinds of food processing machinery, such as ice cream cone machine, frying machine, peanut candy machine, nut processing machine and so on.

- BUSINESS TYPE Exporter, Manufacturer, Supplier

- EMPLOYEE COUNT 200

- ESTABLISHMENT 2010

- ANNUAL TURNOVER USD 5 Million

- CERTIFICATION ISO9001

- WORKING DAYS Monday To Friday

- PAYMENT MODE Letter of Credit (L/C)

Explore Related Categories

Send Enquiry to Supplier

Henan Gelgoog Machinery Co., Ltd.

To: